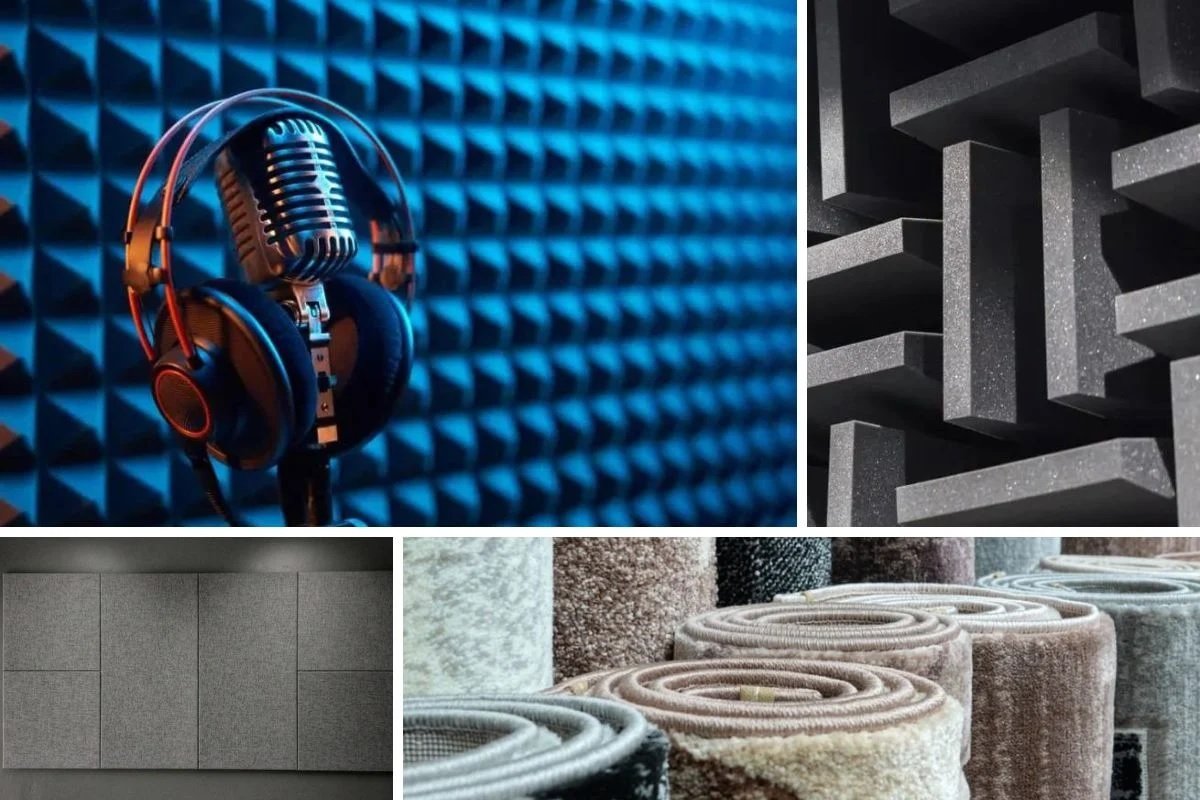

Soundproof mats help control noise levels in a building or room. These mats block and absorb sound waves to prevent noise transfer from one room to another, which is beneficial in multi-residential buildings and business premises. You can also use sound mats to improve sound quality in facilities like music studios and performance theaters. The effectiveness of a sound mat depends on the materials used in its construction. Here are some materials used to make acoustic mats:

Rubber

Manufacturers may use recycled rubber rather than new rubber to create soundproof mats, which makes them an environmentally friendly choice. These mats are dense, which helps them absorb and dampen impact vibrations from sources such as machinery and construction. Rubber mats compress and decompress upon impact, spreading sound vibrations to reduce transmission across the surface. Due to their density, rubber acoustic mats are resistant to tears and punctures, helping them withstand high foot traffic. Construction crews use rubber mats as an underlay for concrete floors, and you may also find rubber mats in gyms and industrial facilities.

Mass Loaded Vinyl (MLV)

MLV is a sound mat material made from vinyl or polyvinyl chloride infused with high-mass compounds like barium sulfate or calcium carbonate. Despite its density, MLV is lightweight and flexible, making it easier for construction crews to transport and shape during installation. MLV acoustic mats come in varying thicknesses, so it is advisable to consult your supplier for guidance on the appropriate density for your needs.

Foam

Due to their porous nature, foam materials work well for soundproofing. The open cells in acoustic foam capture soundwaves and keep them from reverberating off other surfaces. Foam mats work well in environments like home theaters and recording studios, where noise control is needed. This could be a good choice if the home theaters or studios share walls or floors with occupied rooms.

Unlike open-cell foam, closed-cell foam acoustic mat material reduces echoes by creating a barrier to block external noise. The closed-cell structure in these sound mats enhances their ability to reduce impact noise, making them an appropriate option for noise reduction between floors. Acoustic foam is lightweight, making it easy to install on walls, doors, and ceilings.

Fiberglass

Fiberglass is a porous material comprised of thin glass strands woven together to create a flexible soundproofing mat. Sound waves enter the spaces between the fiberglass strands, allowing fiberglass mats to absorb their vibrations. Gel or plastic-coated acoustic mats made from fiberglass reduce and control soundwave reverberations and echoes within a room. These mats have Noise Reduction Coefficient (NRC) ratings of 0.55-0.70. Ratings in this range mean that fiberglass mats are an ideal soundproofing solution for low-noise environments like private residences and office spaces.

Cork

Acoustic mat manufacturers use cork bark to make cork sheeting, a soundproofing material with air pockets for sound wave absorption. Once sound waves enter the air pockets in a cork sheet, they bounce off the surfaces in the air pockets. As they bounce off the cork’s pocket surface, they expend all of their energy. The open structure of cork sheeting makes it difficult for soundwaves to escape through the material, effectively reducing noise. When installed on floors, cork mats compress upon impact, reducing contact noise transmission.

Reduce Unwanted Noise with a Sound Mat

The materials used for soundproofing determine the quality of noise reduction you can expect after it is installed. Most acoustic mat materials can either absorb or block noise, but some, like MVL, have both types of noise-reducing capabilities. Understanding which sound reduction features are optimal for your property can help you choose the right soundproofing solutions. Explore the pros and cons of different sound mat materials to choose one that suits your needs.